E-11 ANH

Project: E-11 ANH

https://www.3d-props.com/blasters/e-11-types/e-11-anh/

Scale: 1:1

3D Printed,

CR-10 V2, PLA

Design credits: Skylu 3D

We wil guide you step by step in the process of building this blaster.

You can find the KIT in the regular shop.

If you have any questions feel free to send us a message on Facebook or Patreon or by mail.

E-11 ANH TUTORIAL BY BRENT

ANH E-11 Made by 3D-PROPS Preparation, assembly and finishing write up.

Tools and Materials:

1. 120 and 180 grit sandpaper

2. 150 and 180 grit sanding sponges (finer sanding grits if desired)

3. curved sanding block, small sanding block

4. small metal files selection

5. shop knife and craft knife

6. Brush and cloth for dusting and cleaning parts

7. Polyester car body filler

8. Sandable flat black primer

9. Glue: I use a polyurethane silicon style glue, super glue also useful.

10. Drill, Dremel, and a heat gun, a Vernier is also useful.

All parts go through certain steps depending on how “bad” or rough the 3-D print texture is. The resin printed parts typically did not need 120 grit sanding

and only needed light sanding.

1. Rough sanding 80 or 120 grit. Note: none of the prints I have had from Eelco have needed 80 grit sanding I start at 120 or 180 sand paper.

2. Filling with polyester body filler. This is only needed for the worst parts or gaps and holes that need filling.

3. Fine sanding 180 grit paper or sanding sponges, although the grit numbers are 150 and 180 on the sponges they give a much smoother finish than sandpaper of the same grit rating.

4. Spray with sandable primer. Note: I don’t use spray putty, I find body filler does most filling of rough areas and sandable primer gives me very low body/volume filling in some areas.

6. Finer sanding, should only be sponges after the first coat of primer.

7. Spray with primer or final colour. Repeat step 6 until desired finish.

Pic 1. Inventory of Parts

All the 3-D printed plastic filament parts needed rough sanding with 120 grit, then 180 grit sandpaper. The resin only really needed sanding with 180 grit followed by sanding sponges, after some trimming of any supports or odd bits.

Pic 2. Orange plastic and Green Resin parts. Pic 3. All parts grey and black.

So I sanded and primed the orange plastic and green resin parts first. Because they were relatively easy, it made my progress photos look better. And you want a number of layers of black on them

so you don’t have any scratches or scuffs suddenly reveal these colors on your finished blaster.

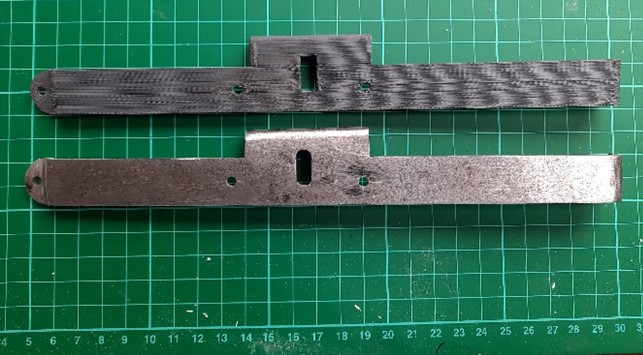

Pic 4. Metal and plastic scope rails.

One of the issues I mentioned was the scope rail, plastic doesn’t handle the weight and tends to bend or sag. Also a few metal parts can really improve the look and weight of a

3D-printed kit.

Pic 5. Folding stock assembly, filler used.

A polyester car body filler is excellent for filling in some of the rougher 3-D print texture after you have roughed it up with some sandpaper.

Pic 6 and 7. Sanding preparation before gluing, grinding back PVC pipe to clear slot.

You need to sand any painted surfaces that need gluing.

You also need to Dremel back some of the PVC pipe in the barrel sleeve so the front sight block will slide into position.

Pic 8 and 9. Folding stock retaining slot, Bayonet lug.

You also need to cut out the PVC pipe to clear the retaining slot for the folding stock’s

hook. I used a small high speed cutter on my Dremel. I also used my Dremel to cut the bayonet lug to fit the circular hole better and to make this accurate curved cut to one of the

corners.

Pic 10 and 11. Backing ABS sheet for strengthening ammo counter assembly.

The resin ammo display didn’t have an adequate seat to make a strong connection to the frame I also wanted to reinforce some other connections. I trimmed the backing sheets to

size and shape using a folding shop knife, test fitted then assembled.

(NOTE THIS HENGSTLER IS REPLACED WITH OUR NEW IMPROVED HENGSTLER NOT SHOWN IN THE PICTURES)

Pic 12. I painted the ammo counter display separately before gluing into position.

Pic 13 and 14. Trigger tension assembly and fitting to barrel.

You need the pin, small tension spring and small phillips head screw to make the trigger have tension. Drill a small hole into the trigger for the screw, punch the pin through

one hole in the housing, THEN slip the spring over the pin, then hammer through the other hole, then carefully get the screw through the other end of the spring and tap it in. Also don’t fit the

trigger guard until you have screwed the housing with trigger into the barrel.

Pic 15 and 16. Filling the seam between barrel halves, detail screw in magazine.

There shouldn’t be a seam between the barrel halves, some filler, sanding and primer fix this. Also the short dome head M3 allen screw provides the detail in the magazine. You

need to drill the hole out first. Although if you are concerned about accuracy this should be a solid dome head rivet not a screw.

Pic 17 and 18. Finished ammo counter, final pre-assembly.

One accuracy point about the ammo counter. It should actually have a clear acrylic strip with the long edges rounded. I did not have any clear acrylic and would have had to

deepen the seat I had made fit this clear strip in. Better reference for this piece can be found on whitearmor.net

The majority of this kit screws together, some parts fit together with how tight their fit is, and some parts glue together. A bit of sanding can ease the fit of some of the barrel and

cap sections that insert into each other. Most of the kit assembles really well and was easy to figure out.

One last point about accuracy, the oval strap ring that goes in the end cap at the rear of the gun. You might notice I have not glued it on. The oval rings supplied were not long enough to fit,

so I looked online to find a more accurate ring that fitted. The ring can also be made out of 3mm metal rod if you have the skill and tools to bend it to the correct shape.

(NOTE THIS HENGSTLER IS REPLACED WITH OUR NEW IMPROVED

HENGSTLER NOT SHOWN IN THE PICTURES)

Brents E-11 ANH build, a great job and thank you so much for the tutorial and good feedback.

Some of the comments have been taken out as they where ment to be as feedback for 3D-PROPS.

I always value honesty and good feedback, it helps improving our kits so if you have any please drop a mail ;)