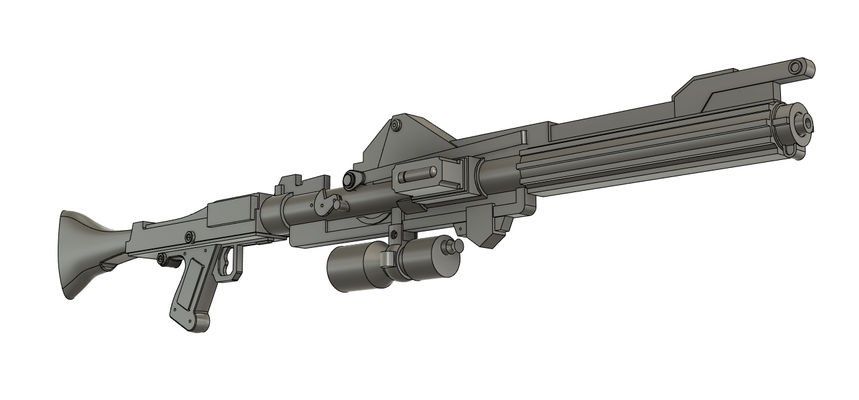

DC-15A BLASTER RIFLE

Project: DC-15A BLASTER RIFLE

Scale: 1:1

3D Printed, FDM, CR-10 V2

https://starwars.fandom.com/wiki/DC-15A_blaster_rifle

FILES WILL BE RELEASED JULY 2021

Design credits: Skylu 3D

We wil guide you step by step in the process of building this blaster.

You can find the KIT in the regular shop.

If you have any questions feel free to send us a message on Facebook or Patreon or by mail.

RnD PHASE

We are going for the Battlefront II DC-15A variation as there are a couple of them, Clone Wars, Attack of the Clones and BF2. I picked this one just because I like the looks of it a bot more due

to its more realistic looks.

Btw some of the pictures are exposed to extra light and contrast to get a better look at the details.

THE DESIGN PHASE AND FINAL MODEL

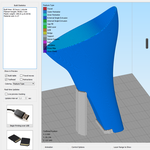

SETTING UP THE FILES FOR 3D PRINTING

With setting up the files in Simplify 3D I made sure everything had plenty of support, enough wall thickness and infill. Variable of the part its wall, top and bottom 5x5x5 with 145%

infill.

Smaller parts are 2x2x2 with 100% infill.

Also I made sure to group some parts together so they can have the same settings and to match some weight. I aimed for using a new 1kg spool for each set of G-code to end up close to that

1kg.

If you check the 3 pictures of Receiver Upper Front LR you can see how I split it in two processes. Goal was to speed the print up, not to waste to much material and still have a strong and super

sharp top surface.

Slicer used: SIMPLIFY 3D

All 3d printed parts, screws and tube

All the (printed) parts together.

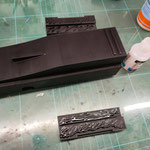

Section assembling and prepping for the paint job

In the photos above you can see the process from combining the main sections of the blaster to make assembling and prepping the blaster for the paint job easier. Because this is a very forward

build and with areas with easy acces for sanding in all corners and edges I went for assembling the sections first instead of doing each part separately. Of course youre free to do as you

like/prefer.

After the section assembly we gave everything a UV cured resin coat. Sanded it with 150 - 240 . Cleaned it and added a primer layer to see the areas of interest for an extra sand job.

After a second layer of primer we added two layers of mat black of any particular brand.

With the two layers of mat black the wet sanding with 600 was in order before adding the final mat black layers. In the last picture you can see the final result just before the weathering.

WEATHERING VIDEO